Acceleratuion shock test equipment

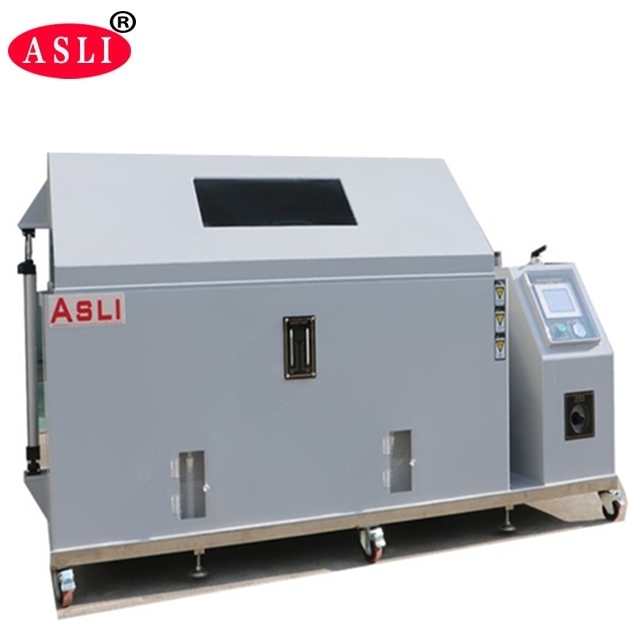

Salt Spray Test Equipment For Plating

MOQ :1 set

Lead Time :20 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Western Union

Departure Port : ShenZhen

Product details

Supply Ability

- Supply Ability:10 piecesWarranty(Year):1 Year

Packaging & Delivery

- Length:230 cmWidth:140 cm

- Height:130 cm

- Packaging:1 set

Product Specifications

- Brand name:ASLI

Product Description

Salt Spray Test Equipment For Plating

Salt fog test chamber/features:

1.Adopt automatically or manually adding water system, can watered by itself while lack of water.

2.Precise glass spray nozzle, good uniformity, mist dropping naturally, no NaCl crystallized salt

3.Double over-heat protection devise and alarm when water short storage to ensure use safety.

4.Digitally temperature controller, PID controlled, precision of about 0.1 celsius degree

5.Laboratory direct steam-heated, even heating speed, reducing the standby time.

6.Tapered Spray tower, even mist dropping

7.Saturated bucket is SUS #304, convenient for heating and humidifying, offer humidity for testing

8.Concentration of NaCl: 5%; PH of the water: 6.5-7.2 (Liquid)

Warranty: one year free warranty for whole set machine,lifelong time maintainance.

After-sale service: feedback within 2 hours after get the call.

Service:OEM service,Design service,Buyer lable service.

Salt Spray Chamber/technical parameters:

1.Model:SH-160

2.Internal Dimension WxHxD (mm):1600x800x500

3.External Dimension WxHxD (mm):2300x1300x1400

4.Saline Concentration:5% concentration of NaCl, or every Liter 5% NaCl add 0.26g CuCl2H2O

5.Compressed Air Pressure (Kgf): 1.0~6.0

6.Pressure Bucket Temperature: Saline test method (NSS ACSS) 47 about 1 celsius degree /Corrosion Test (CASS)63 about 1 celsius degree

7.Lab Capacity (L):800

8.Saline Capacity (L):40

9.Power: AC220V 1∮ 3 lines15A

10.Weight (Kg):160

Spray Chamber/application:

Salt Spray Test Chamber is specially designed for the testing of the corrosion erosion resistance of the products after their material surfaces have been treated with electric plating, anodizing, spray coating, anti-rusting oil and other anti-erosion treatment.

You May Like

- Free Member

- Trade Assurance

Business Type : Manufacturer,Trading Company

Company Location: GUANG DONG

Year Established: 19YRS

You May Like

-

Acceleratuion shock test equipment

-

LED test equipment

-

Carton simulating transportation vibration test table

-

Temp humi vibration test chamber

-

Aging air ventilation chamber

-

Steam chamber

-

High Temperature Aging Test Equipment

-

Temperature Humidity Vibration Test System

-

Xenon arc Light and Weather Fastness Tester

-

Incline shock impact testing tester manufacturer